HACCP - Hazard Analysis Critical Control Points

HACCP - Hazard Analysis Critical Control Point isinternationally recognized certification for managing and controlling the food safety, legality and quality related issues. It is based on seven HACCP principles which addresses the analysis and control of all physical, biological and chemical food safety Hazards.

The HACCP certificate is suitable for all manufacturing companies in the food and beverage sectors along the entire production chain. Implementation of HACCP is already mandatory in Europe and the USA, but other countries are placing increasing emphasis on certification, and so an HACCP certificate is worthwhile for all organizations which export abroad

TÜV NORD is represented and respected all over the world. Our auditors have in-depth knowledge of food safety combined with an interdisciplinary approach and undertake intensive annual training in order to remain ahead of the field. This means that we can offer the possibility of combined audits which cover several different standards

Benefits of HACCP Certification

- You secure the trust of your customers.

- Focus on preventive actions helps to avoid unnecessary costs.

- You use your resources effectively to produce trustworthy food.

- With an ANSI (American National Standards Institute) accredited certificate you demonstrate consistent use of the HACCP concept

- The HACCP concept ensures compliance with legal regulations and reduces food safety risks (i.e. product liability risks), ensuring better food quality.

- This creates trust on the part of consumers and customers.

HACCP certification defines the requirements for effective control of food safety based on seven principles

- Conduct a hazard analysis of all physical, chemical and biological hazards

- Identify the critical control points.

- Establish critical limits.

- Establish critical control point monitoring systems.

- Establish corrective action programmes

- Establish verification procedures for effective working on HACCP

- Establish documentation keeping procedures.

- Planning and preparation of the audit

- Performance of the certification audit: Document review and on-site inspection

- Determination of the audit rating

- Issue of the certificate

- The certificate is valid for three years, followed by recertification

FAQ'S for HACCP Certification

What kinds of organizations need an HACCP concept?

All manufacturing companies in the food and beverage sector along the entire production chain in Europe and the USA are obliged to implement HACCP. But an HACCP certificate is also very important for other countries, in particular for all companies who export abroad.

Is certification to HACCP accredited?

The German Accreditation Council withdrew from accreditation for HACCP as early as 2017. The reason is that HACCP is now a legal requirement and therefore is no longer a voluntary standard, and it is not used as a basis for ISO 22000. We therefore sought an alternative accreditation, which is valid throughout the world, and we offer our clients accreditation to the American accreditation body ANAB. ANAB is the ANSI (American National Standards Institute) National Accreditation Board

What does HACCP mean?

HACCP stands for Hazard Analysis Critical Control Points. The HACCP certificate covers processes in food manufacturing and services in the food sector and specifies the necessary hygiene requirements for the manufacture of safe food, which is suitable for human consumption. The HACCP certificate can be used for all organizations and all stages within the food chain: from primary production through processing, storage and distribution to retail outlets themselves.

What is the procedure for HACCP certification?

From the start, you will work with a competent team of experts from TÜV NORD CERT, who will provide you with independent and neutral support.

Our services:

- Planning and preparation of the audit

- Performance of the certification audit: Document review and on-site inspection

- Determination of the audit rating

- Issue of the certificate

- The certificate is valid for three years, followed by recertification.

Is certification to HACCP accredited?

HACCP stands for Hazard Analysis Critical Control Points. The HACCP certificate covers processes in food manufacturing and services in the food sector and specifies the necessary hygiene requirements for the manufacture of safe food, which is suitable for human consumption. The HACCP certificate can be used for all organizations and all stages within the food chain: from primary production through processing, storage and distribution to retail outlets themselves.

The following product categories are used for HACCP certification:

- Farming of animals, fish and plants, HACCP categories A and B

- Food manufacturing, HACCP category C

- Animal feed production, HACCP category D

- Catering, HACCP category E

- Distribution (wholesale and trading), HACCP category F

- Retail, transport and storage, HACCP category G

- Services for the food industry, HACCP category H

- Manufacturing of primary or secondary packaging materials, HACCP category I

- Manufacturing of machinery with food contact and vending machines, HACCP category J

- Manufacturing of food and animal feed additives, manufacturing of chemicals, HACCP category K.

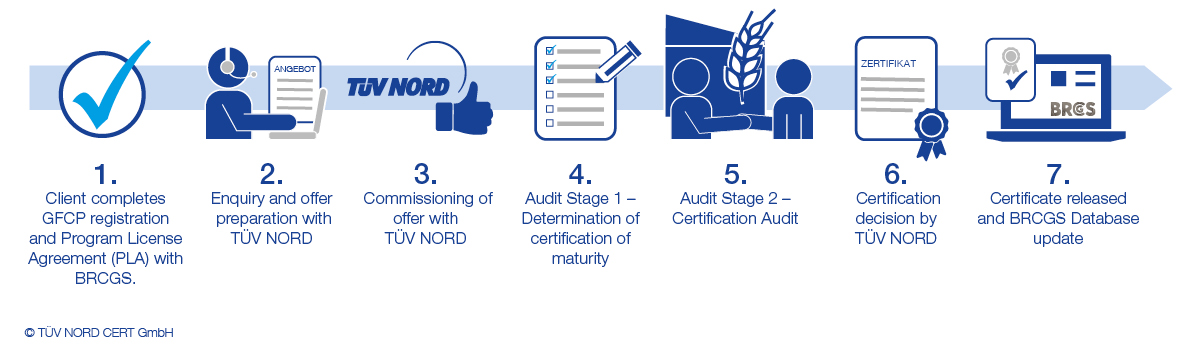

How to reach BRCGS Gluten-Free Certification Programme

TÜV UK LTD Certification: The benefit to you

TÜV UK LTD is recognised all over the world as a well-established and reliable partner for inspection and certification services. Our experts and auditors have in-depth knowledge and many years of experience in the food sector, and undertake annual training in order to remain ahead of the field. We can guarantee independence, neutrality and continuity in all our services to you, and the benefits are clear. Our experts support the development of your products and provide you with objective feedback.

As our auditors are qualified in several fields, we can also offer efficient and cost-effective combined audits (e.g. with other management systems / food safety systems).

We are looking forward to your enquiry

Suites 27 - 29, Fifth Floor, Dingwall Road

Croydon, CR0 2LX

Tel.: +44 20 8680-7711

Enquiries.UK@tuv-nord.com